Overview

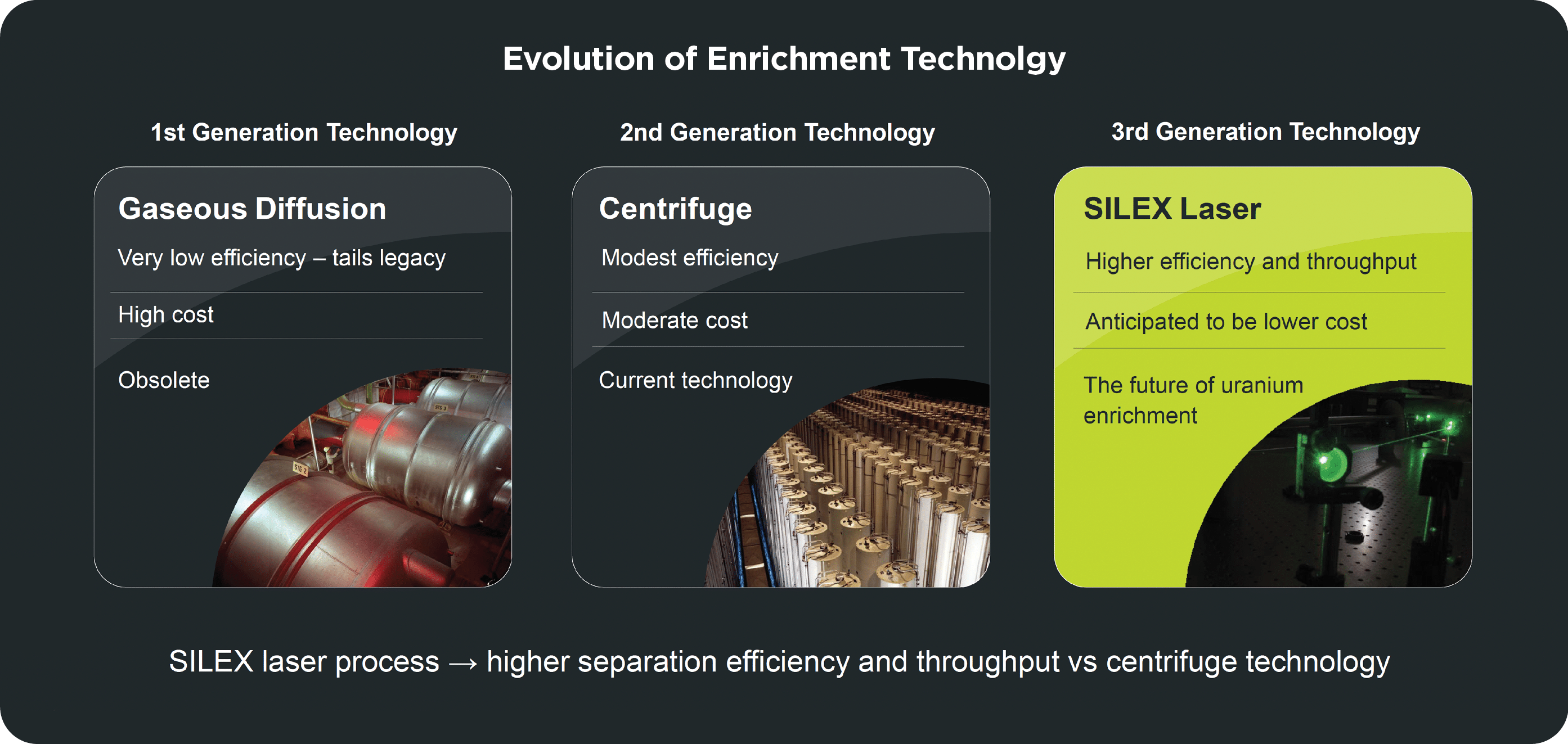

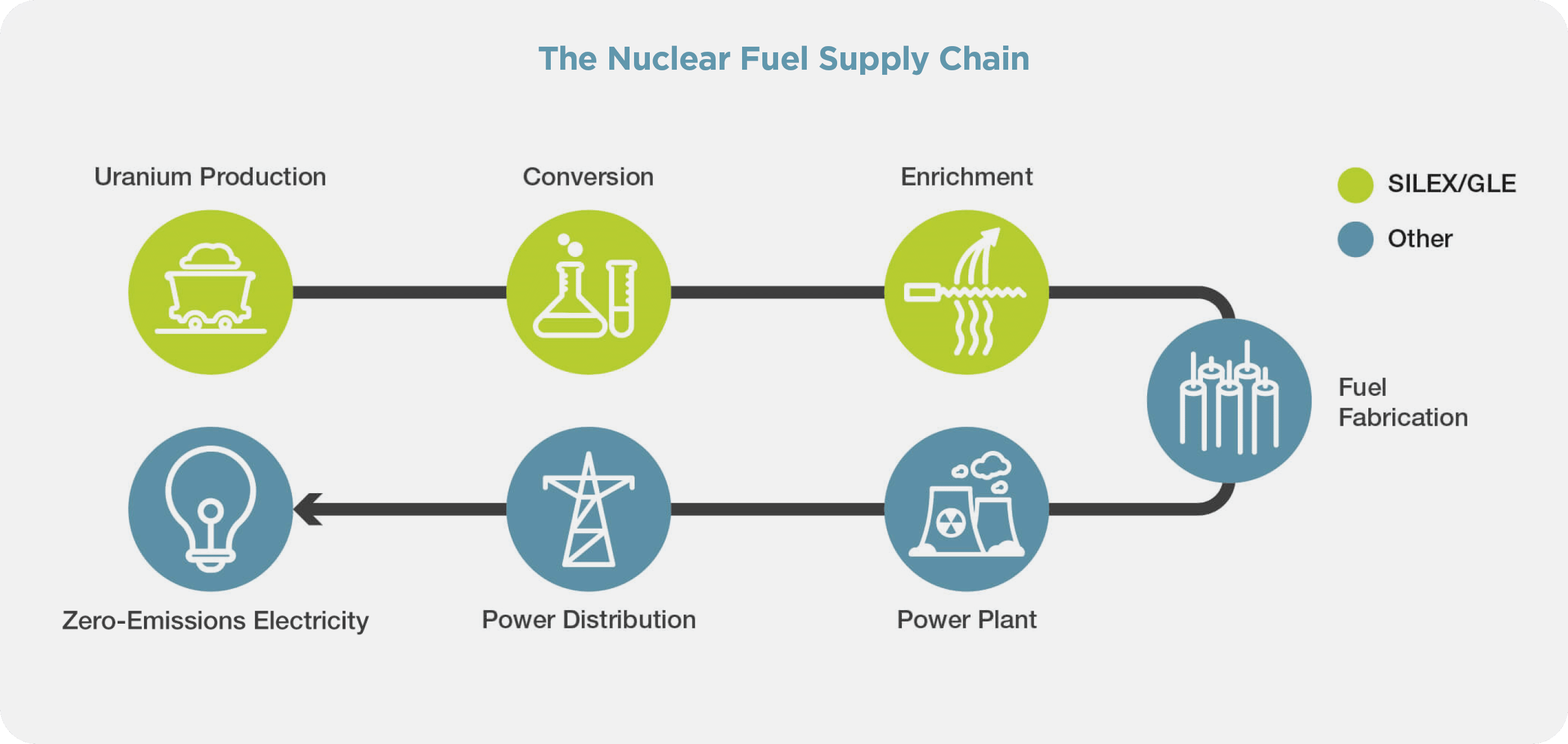

- Silex invented and developed the ‘SILEX’ laser isotope separation technology in Sydney during the 1990s. The uranium enrichment application of the SILEX technology was licensed exclusively in 2006 to Global Laser Enrichment LLC (‘GLE’), a joint venture business today owned by Silex (51%) and Cameco Corporation (49%).

- GLE is the US-based commercialisation vehicle for the SILEX uranium enrichment technology.

- The development and commercialisation program for the SILEX uranium enrichment technology is being undertaken jointly by Silex (at its Lucas Heights, Sydney facility) and GLE (with sites in Wilmington, NC and Paducah, KY).

- The SILEX laser uranium enrichment technology achieved Technology Readiness Level 6 (TRL-61) in October 2025.

1. Technology Readiness Level 6 (TRL-6), as defined by DOE Technology Readiness Assessment Guide (G 413.3-4A)